Making appropriate choices is not always easy as they depend on characteristics of the engine, In a single cylinder engine choices in terms of balance and inertia of the crankshaft engine are fundamental both for what concerns the reliability (loads on the frame, vibrations, etc.),īoth for performance, in fact influence the amount of friction and then the engine power, acceleration,

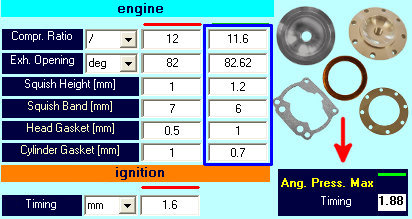

Thanks to the help of tested formulas for intake, exhaust, Moreover you can have advices for the development of the engine Port areas and the timing area in the engine cycle timing for each phase. Two Stroke Design instead you can enter theĭata of your cylinder with extreme facility and precision, and then analyze the The analysis of the timing and the timing area of the cylinder ports, essential to evaluate the operation of the engine and decide how to intervene in the development, often is difficult and can not be made in an easy and precise. Valve and study the petals most appropriate also with solutions that use withįiber stopper or spacers interposed to obtain stiffness variables and increase the performance Reed Design can instead analyze the behavior of your reed Often you've been forced to use the reed petals proposals on the market, without being able to take significant action. To the engine is essential to maximize the performance starting from the intake phase. In the 2-stroke engine with reed valve admission, the identification of petals more adapted to the reed valve and In addition to defining the geometry of the insert, itĪlso indicates the processing steps for its craft realization. The flow to the advantage of performance. The shape of the reed valve causes significant fluidĭynamic losses to the fluid flow that comes from the intake manifold, therefore a part of the pressure difference generated by the crankcase is expended to overcome these lossesĪt the expense of the reed opening. Moreover, the software provides the data and theĭrawing of the bellmouth for an easy realisation with CNC machines.

Thanks to the softwareīellmouth Design, instead you can quickly find the most suitable geometry of the cornet to maximize the efficiency of the carburetor. To improve this situation it is customary to study cornets to apply to the carburetor, but often the determination of the optimal geometry is difficult to detect and you have to make several and expensive attempts. The losses at the entrance of the carburetor reduce the effective diameter of the carburettor and then

0 kommentar(er)

0 kommentar(er)